Number of transaction per year

2500+

Number of companies using our products

2000+

Experience of manufacturing

65years

Range of Industries

+168

High-quality, TB-Niigata swivel joints reduce leakage, maintenance frequency, and life cycle costs.

Free DownloadContact Us

Transactions per Year

2,500+

Companies Using Our Joints

2,000+

Years of Experience

65

Customer Industries

+170

Important Announcement

We are pleased to announce an important update regarding our brand strategy at our company.

As part of this initiative, we have decided to unify the brand names of our products, namely "CHIKSAN," "WECO," and "NIIGATA," under the new name "TB-NIIGATA."

For over half a century, we have been dedicated to the development, manufacturing, sales, and maintenance services of energy-related machinery, including loading arms, swivel joints and butterfly valves.

Through this brand name unification, we aim to solidify our brand image, improve our services, and become an even more reliable partner for you, our esteemed customers.

Effective from and after July 1 , 2023

Number of transaction per year

2500+

Number of companies using our products

2000+

Experience of manufacturing

65years

Range of Industries

+168

What Are Swivel Joints?

A swivel joint is a specialized rotational piping joint designed to perform rotary or linear motion in vertical, horizontal, or forward/backward directions.

This functionality is essential when transporting fluids or gases through pipelines. Achieving 360-degree rotation is made possible by the combination of two-row ball bearings and two components, facilitating the free movement of pipes during fluid transportation.

TBG is a leading manufacturer of swivel joints under the brand name TB-NIIGATA. These swivel joints are integral to a wide array of process machinery across several industries, including:

Chemical,

Petroleum,

Aviation,

Refining,

Mining,

Steel,

Beverage,

Paint,

Daily Food,

Pharmaceutical.

What is the diffrence with Rotary Joints ?

While both swivel joints and rotary joints are crucial in fluid dynamics, they serve different purposes and applications.

A rotary joint, also known as a rotary union, forms a flow path for water, air, oil, and other fluids between a fixed pipe and a rotating shaft.

This mechanism allows for the continuous supply of fluid to a rotating body, facilitating the circulation of the fluid.

Features

Fluid Type Range:

725

Maximum Pressure:

34 MPa

Nominal Diameter (ND) Range:

3/8"–30"

Temperature Range:

-50 to +200 ℃

Choose from 9 Types

Other Features

- Unique Packing Structure provides a more reliable seal for longer than O-rings.

- Trapezoidal Cross-Section prevents leakage due to twisting, as with O-rings.

- Outer Ring prevents the packing from protruding into the joint and damaging the seal.

Models to handle under -50 °C or over 30" are also available.

Please contact us for details.

A Wide Range of Swivel Joints

Sanitary Swivel Joints (NS)

TBG is the only manufacturer and distributor of sanitary swivel joints in Japan and has a long history of working with customers in over 50 industries.

Niigata sanitary swivel joints are designed for hygienic piping applications and are compact and lightweight, making them easy to disassemble, clean, and reassemble for improved process piping maintenance.

Submerged / Subsea

Swivel Joints

(Double seal)

In 1950, Niigata Enginering developed an original swivel joint for submerged service to address the Japanese oil industry's needs, designed to accommodate draining lines for floating roof tanks.

Soon, this product became the enabler for safe and reliable operations of 2,600 floating roof tanks at our customers' storage facilities.

High-Pressure Swivel Joints (Silver)

High-pressure TB-NIIGATA swivel joints are used in various industries for high-pressure hydraulic, air, and cooling lines. They absorb vibrations and deformations in piping systems.

Extra High-Pressure Swivel Joints (Orange )

Extra high-pressure TB-NIIGATA swivel joints are specially designed and built with 2–1/2B–5B triple ball races for extreme pressure and high load scenarios. Use cases include oil drilling, iron, and various industrial machines.

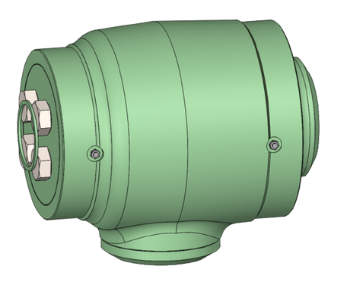

Low-Pressure Swivel Joints (Green)

One of Our Best-Selling Models

Low-pressure TB-NIIGATA swivel joints are used in various kinds of installations for operations. They are widely used in loading racks and flexible lines for handling all types of materials.

Low-Pressure Swivel Joints (Blue)

One of Our Best-Selling Models

Low-pressure TB-NIIGATA swivel joints are used in various kinds of installations for operations. They are widely used in loading racks and flexible lines for handling all types of materials.

Stainless Swivel Joints

These stainless steel TB-NIIGATA swivel joints are mainly used for cryogenic service and corrosive substances. Additional Option: Snap-in ball races for resistance against a heavy load.

Pressure-Balanced Swivel Joints (NSB)

NSB and NPB have pressure-balanced structures which enable them to withstand water hammers and vibrations under high operating pressure.

Pressure-Balanced Swivel Joints (NPB)

NSB and NPB have pressure-balanced structures which enable them to withstand water hammers and vibrations under high operating pressure.

- Catalog will be opened to you immediately upon receipt of your information.

- You can see the detailed specification data of each product in the catalog.

- You can get a free catalog.

- We will help you choose the best product for your needs.

- Available in both English and Japanese.

- Our professional staff will provide you with detailed customer service.

Applications

スペック関連を掲載予定

Creative Filters

Unique effects

3.0 (7.5 cm) type

LCD screen

24.1 megapixel

APS-C sensor

Connectivity

Simple shoot

Intelligent Auto

Simple shoot

Intelligent Auto

9 point autofocus

Food, Beverage, Pharmaceutical

Data center and Semiconductor

Sanitary Swivel Joints for Hygenic pipes

Choose from 3 types

Style No.20

Style No.30

Style No.40

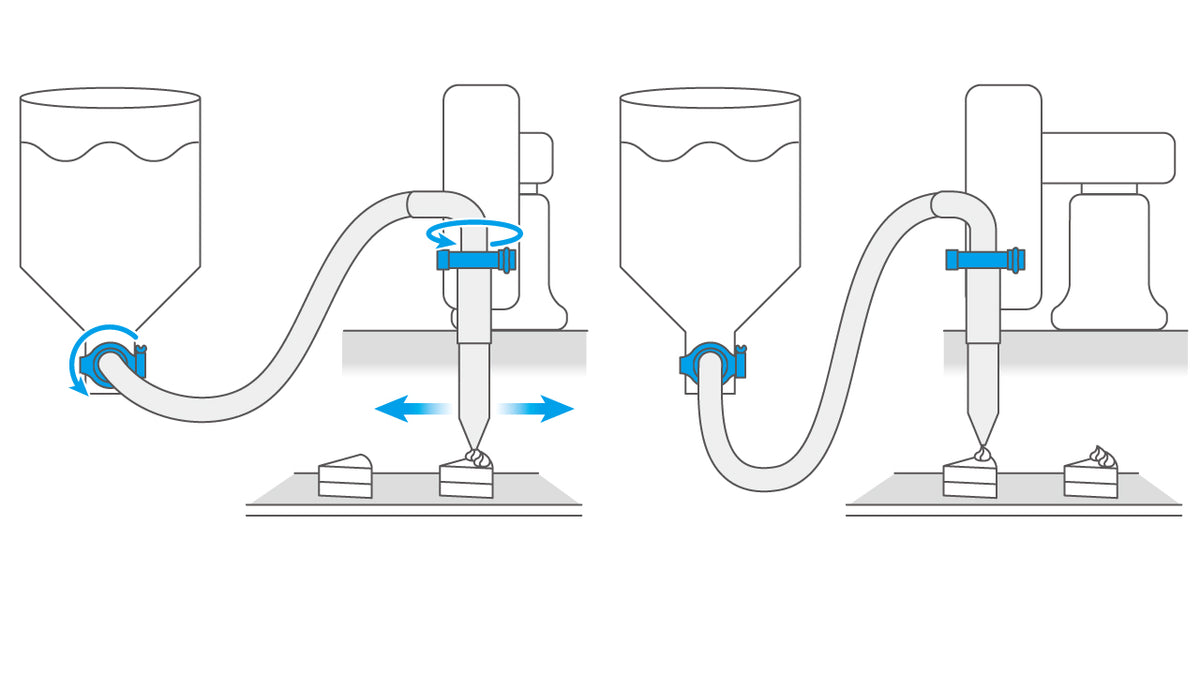

1. You can change the outflow direction and route the piping without loosening tri-clamp band .

2. By attaching it to the base of an existing hose, it prevents the hose from being twisted or damaged.

3. Since the hose length and bending radius can be reduced, a compact design is possible, and the piping layout can be easily changed.

How to use sanitary swivel joints ?

Case Study Vol.2

In the cheese factory of a company with over 100 years of history in manufacturing and selling dairy products, the sanitary swivel joint was utilized for smooth operations.

【Problem】

The existing process required

adjusting the piping position for the

opening and closing of the tank lid,

leading to inefficiencies.

The company sought a solution to

improve maneuverability and

efficiency during the process.

【Solution】

Installation of sanitary swivel joints

enabled 360 degrees rotation of the

piping without detaching clamps,

facilitating smooth lid opening and

ingredient pouring.

Swivel joints allowed horizontal

movement, improving overall work

efficiency in subsequent processes.

Changing pipe angle and direction

Benefits

Swivel joint adoption improved operational efficiency and reduced the burden on

employees.

Case Study Vol.6

High pressure extractor

Case Study Vol.1

Filling machine or equipment / Fluid distribution

Case Study Vol.5

Hose necks

Case Study Vol.4

Robot filling arms

Case Study Vol.7

Pipe ends to prevent liquid dripping

Case Study Vol.3

Hopper tank lid open and close

Case Study Vol.8

Pipe line exchange in mixture process

Case Study Vol.9

Changing product flow line

Standard Specifications

Body Material:

Stainless Steel

(SUS316, SUS316L etc., )

Standard Packing :

PTFE + Silicone Rubber (~0.98MPa)

Temperature Range:

-50 to +150 ℃

Nominal Diameter (ND) Range:

1S、 1.5S、 2S、 2.5S、 3S、 4S

(1" ~4")

Non Silicone Packing :

PTFE + Stainless Spring (~0.3MPa)

Grease :

Non-Grease Design

*Other specificaitions are also available.

Please contact us for details.

Fluids

'Beverages - Juice / Coffee / Milk / Yoghurt / Tea

'Food - Ice cream / Sweet Bean Paste / Fish Paste

'Alcohol - Beer / Wine / Whiskey / Japanese Sake

'Seasoning - Soy Sauce / Noodle Soup Base / Barbeque Sauce / Vinegar / Dressing / Cooking Oil / Wasabi

'Others - Fragrance / Paint / Hair Growth Tonic /

Laundry Detergent / Solvent

- Catalog of Sanitary swivel joints will be opened to you immediately upon receipt of your information.

- You can see the detailed specification data of each product in the catalog.

- You can get a free catalog.

- Full case study collection of swivel joints will be opened to you immediately upon receipt of your information.

- You can see the detailed description of each application in the case study collection.

- You can get a free PDF.

Aviation, Chemical Processing

Float Suction Skimmers (FSS)

TBG manufactures and designs floating suction units (FSU),

also referred to as floating suction lines (FSL) or floating suction skimmers (FSS), for use in horizontal or vertical,

above-ground storage tanks to extract the upper layer of the cleanest liquid without contamination.

Our FSUs are equipped with robust and durable TB-NIIGATA Swing Joints

with flange connections designed for long, trouble-free service lives for storage tanks of various shapes.

Loading & Unloading Equipment

Bottom Loading & Unloading

Oil & Gas

Roof Drain System for Floatin Roof Tanks

Niigata floating roof tanks draining systems have a record life expectancy of more than 30 years in operations without significant issues or accidents occurrence.

Their market share is nearly 100% in Japan.

Niigata draining system assembly design allows for permanently stable positioning of the drain inside the tank without possible interference with the floating roof legs when the tank is empty, guaranteeing no mechanical damage of the drain and no abrasion of the tank floor like hose drains would, as a result as not being guided inside the tank.

- Catalog of Roof drain system will be opened to you immediately upon receipt of your information.

- You can see the detailed specification data of each product in the catalog.

- You can get a free catalog.

Submarine Hose Neck

LPG Filling Machines

Burner Joint Assembly

Marine Loading Arms

Steel Processing & Industrial Machinery

Hose Necks

Swivel joints are widely used to connect pipes and hoses to prevent leakage or bends.

Transportation Hose Neck

Filter Press Machine

Hydraulic Hose Neck

Steel Processing Machine

Slury Pump Hydraulic Line

Articulated Piping Systems

Combining multiple swivel joints makes it possible to follow the movement of the X, Y, and Z axes in three dimensions.

We design and produce swivel joint assemblies

based on the customer's working range on the movable side and service conditions.

Steel Processing Super High-Pressure Joint Assembly

Steel Processing Super High-Pressure Joint Assembly

Steel Processing Hot Strip Mill Descaling

Swivel joint Joint Assembly for Vacuum Sludge water

Articulated Piping Systems for movable platform

Transportation

Airport Refueling Vehicles

Hose Reels in Bulk Trucks

Fuel Refueling Trucks

Construction

Willow

As a moving pipe, it is more rigid than a hose and can handle even the largest variations by simply changing the pipe's length. It can be installed in a small space because its length is extremely short in relation to the required displacement, which is typically a problem for high-pressure hoses.

Our hoses are made of steel pipes and have a specially coated sealing material to ensure high durability and pressure resistance. Steel pipes minimize the risk of rupture, making them exceptionally safe for use in high-pressure fire-extinguishing piping.

Example Fluids:

•Domestic wastewater, air, N2 gas, CO2 gas, LP gas, CFC,halon, etc.

• Oil-based systems such as kerosene and light oil, NH3, etc.

About Us

In 2021, TB Global Technologies Ltd. (TBG) was established through the merger of Tokyo Boeki Machinery Ltd. and Tokyo Boeki Engineering Ltd. that was formerly known as Niigata loading systems ltd. and Niigata Engineering ltd.

We have been creating new values by gathering the strengths we have accumulated for more than half a century, and putting together the value chain from marketing to development / manufacturing / sales / after-sales services.

Our Customers' Countries

Over 2,000 companies worldwide choose our MADE-IN-JAPAN products for their safe and stable operation. reliability and case of use.

Other Products

TB-NIIGATA Butterfly Valves

TB-NIIGATA Butterfly Valves can meet a wide range of application needs with specific conditions such as highly heated, highly-pressured, vacuumed, anti-corrosion, realizing long product life simultaneously.

Features

An integral seat structure realizes excellent sealing performance stuck with backup rings to be more resistant to friction so that we can provide reliable Japanese valves guaranteed with a long product lifetime.

The light and compact design also help to install in complicated delivery sites, carrying it easily. Our butterfly valves are manually handled but suitable for automation systems and up-sizing requirements.

Models

M12 (2" ~ 12")

M44 (14" ~ 24")

(N15 (2" ~ 8")

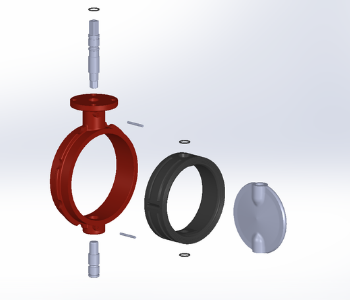

TB-NIIGATA Wing Unions

The Ueco Union is mainly used to connect excavation piping. By alternating swivel joints and pipes, it solves the problems of complicated movement and twisting that occur in long, high-pressure piping.

Features

• Easy to attach and detach pipes

• Compact and easy to replace seals

Use Cases

• Hot spring drilling machine

• Cement machine piping

• Surface and subsea piping for oil drilling machines

Models

FIG 602(6000 psi)

FIG1002(10,000 psi)

FIG1502(15,000 psi)

TB-NIIGATA Ball Joints

The use of Niigata ball joints in piping systems offers the following advantages.

Features

• Simultaneous rotation and tilt are possible, allowing the pipe to follow two or more planar movements.

• Longer pipe life due to low-end thrust.

• Reduces the number and weight of anchors and guides in the piping system, resulting in significant cost savings.

• Provides greater functionality in a smaller space than pipe loops.

• It is safe enough to withstand shock and vibration.

• They are meticulously designed to require little maintenance under all conditions of use.

- Catalog will be opened to you immediately upon receipt of your information.

- You can see the detailed specification data of each product in the catalog.

- You can request a free catalog.

- Catalog will be opened to you immediately upon receipt of your information.

- You can see the detailed specification data of each product in the catalog.

- You can request a free catalog.

TB GLOBAL TECHNOLOGIES LTD.

28F, Kyobashi Edogrand, 2-2-1 Kyobashi, Chuo-ku, Tokyo - 1040031, Japan

TEL : +81-3-6633-6680